Fiberglass & Epoxy

-

Pettit EZ-Fair

$51.88 - $123.95 -

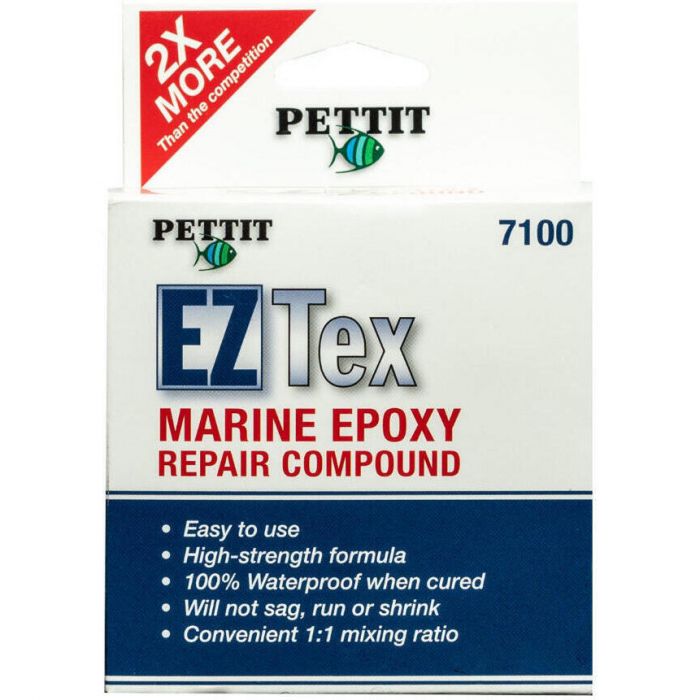

Pettit EZ-Tex Marine Epoxy Repair Compound

$25.74 - $52.30 -

Pettit Splash Zone Epoxy Repair Compound

$116.71 - $489.65 -

Pettit FlexPoxy Epoxy Resin - 7076

$62.68 -

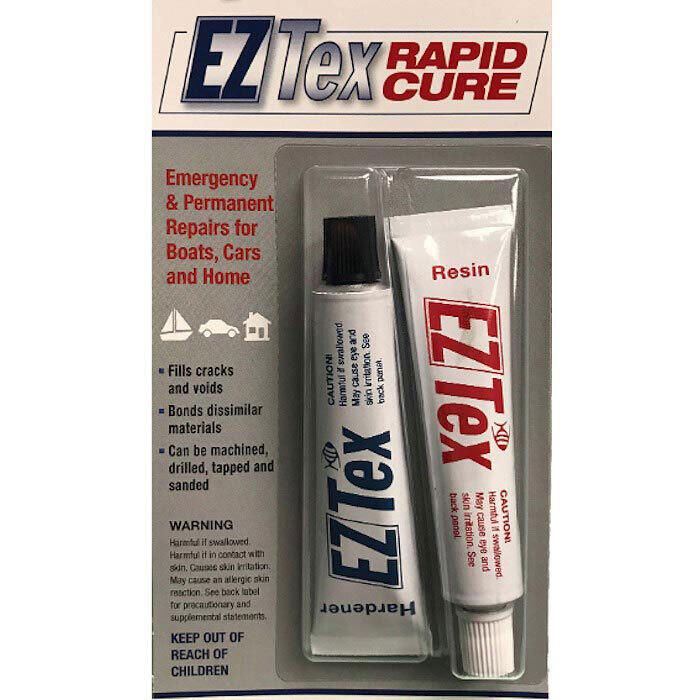

Pettit EZ-Tex Rapid Cure Marine Epoxy Repair Compound - 7200

$23.04 -

Hexcel JPS Preferred Fiberglass Cloth

$10.03

About Fiberglass & Epoxy

Epoxy, Fiberglass & Gel Coat Repair Kits

Gel coat repair kits and compounds range from crack and chip fillers to surface formulas to counter oxidation and fill surface scratching. Some two-part marine fiberglass repair kits come with gloves, stir sticks, and mixing pots. Epoxy compounds for aluminum repairs, fast-cure epoxies, and adhesives are all available at Defender Marine.Regarding construction and repairs, fiberglass is a popular choice for many projects. It is a durable, lightweight material with excellent insulation, corrosion resistance, and low thermal conductivity. In addition, fiberglass can create solid and water-resistant materials that can withstand extreme temperatures and weather conditions, making it an excellent material for building and repairing all sorts of items.

Fiberglass is a composite material made of tiny glass fibers. It is created by melting glass and spinning it into thin fibers, combined with a plastic polymeric matrix. The resulting material is incredibly strong yet lightweight and is commonly used for products like boats.

Fiberglass has several advantages over traditional materials like wood, metal, and concrete. It is much lighter than these materials, making it easier to transport and install. It is also incredibly resistant to corrosion so it can be used in areas with a potential for salt water exposure. Additionally, fiberglass is an excellent insulator, which can help keep your home or business cool in the summer and warm in the winter.

Fiberglass can also be used to repair existing structures other than boats, such as cars and houses.

Epoxy resin is a versatile substance utilized in various industries, including marine, automotive, aerospace, and construction.

One of its main advantages is epoxy resin's strong bonding properties with various substances, such as glass filaments, fiberglass matting, and carbon fibers.

When combined with glass filaments, epoxy resin creates a high-performance composite material ideal for complex shapes. The glass filaments provide strength and stiffness, while the epoxy resin holds everything together and provides a smooth finish. This combination is commonly used in manufacturing boats, airplanes, and other vehicles.

Fiberglass matting is another popular reinforcement material used with epoxy resin. This material is made of short glass fibers that are randomly oriented, which gives it a flexible and conformable structure. When combined with epoxy resin, fiberglass matting provides excellent strength and impact resistance, making it ideal for use in applications such as construction and automotive.

Another material that can be combined with epoxy resin is fiberglass cloth.

It has a smooth surface and is comprised of woven glass fibers.

Fiberglass fabric has excellent strength and stiffness when mixed with epoxy resin, making it perfect for use in aerospace and marine industries.

Carbon fibers are also a popular reinforcement material used with epoxy resin. These fibers are made of carbon atoms that are tightly packed together, which gives them a high strength-to-weight ratio. When combined with epoxy resin, carbon fibers provide excellent stiffness and strength, making them ideal for applications such as aerospace and automotive.

Fiberglass tapes and fiberglass cloth are also popular materials used with epoxy resin. These materials are made of woven or braided glass fibers and are used to reinforce complex shapes and provide a smooth finish.