Windlasses

-

Muir Cougar HR1600 Compact Stainless Steel Horizontal Windlass - MH1600S12-5/16H

$5,203.76 -

TRAC Outdoors G3 Wireless Remote Unit - 69930

$42.88 -

TRAC Outdoors Angler 30-G3 Electric Anchor Winch with AutoDeploy - 69004

$378.53 -

TRAC Outdoors Deckboat 40-G3 Electric Anchor Winch with AutoDeploy - 69005

$420.83 -

TRAC Outdoors G3 Anchor Wireless Winch Remote Kit - 69044

$89.41 -

TRAC Outdoors Anchor Winch Remote and Control Box - 69884

$55.61 -

TRAC Outdoors Davit Assembly for Pontoon 35/Deckboat 40-G3 - 69927

$42.92 -

Lewmar Wired Windlass Remote Kit - 66940002

$210.67 -

Egis Mobile Electric Contactor

$82.36 - $175.42 -

Lewmar Venta Pontoon Anchor Winch Kit

$3,056.20 - $3,321.28 -

Lofrans Conversion Deck Pad - White - LWPDPCON1

$66.85 -

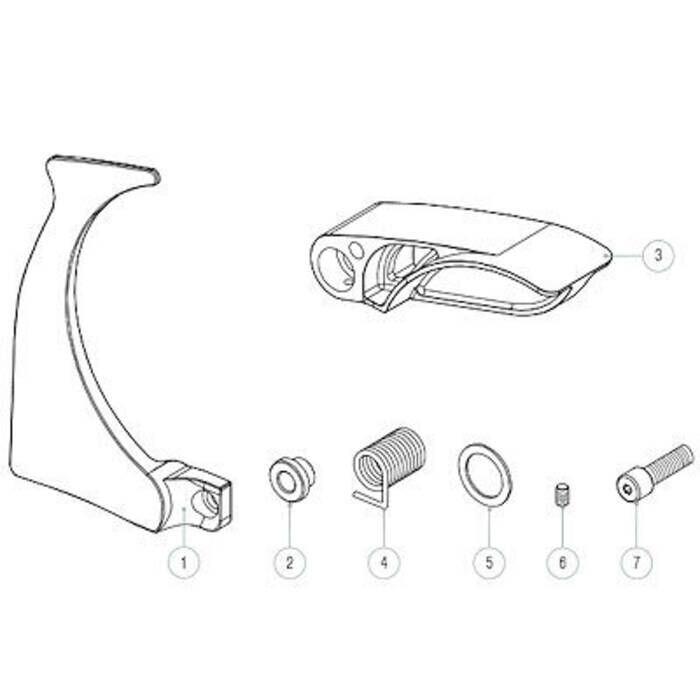

Maxwell Lever Assembly

$283.99 - $360.13 -

Lofrans X4 Vertical Windlass

$11,852.11 - $12,696.13 -

Lofrans Low Amperage Foot Switch

$59.80 -

Lofrans Kobra Horizontal Windlass

$3,301.74 -

Lofrans Electric Motor

$1,032.74 - $3,594.91 -

Lofrans Dorado Horizontal Windlass

$1,740.75 - $1,879.51 -

Lofrans Windlass Gypsy

$233.27 - $1,406.41 -

Lofrans #920 X2/Project 1000 Underdeck Gearbox Flange - LWPDF015

$162.75 -

Lofrans Falkon Worm Screw - 2000W - LWPGP097

$453.21 -

Lofrans #448 Falkon Wormwheel - LWPGP040

$814.19 -

Lofrans #476 Tigres Wormwheel - LWPGP029

$367.20 -

Lofrans Sensor and Magnet Kit

$68.26 - $138.76 -

Lofrans #355 Chain Stripper

$86.59 - $104.92 -

Lofrans Thetis 7003 Hand Held Wireless Remote Control Chain Counter - LWP73633

$818.40 -

Lofrans #212 Dorado Gypsy Top Cap - LWPCA003

$210.67 -

Lofrans #912 X2/Project 1000 Rope Drum Top Cap - LWP821TC

$210.67 -

Lofrans #918 X2/Project 1000 Euro Type Low Profile Top Cap - LWPCA009A

$306.55 -

Lofrans #1050a X1/Project 500 Low Profile Top Cap - LWPCA005

$188.11 -

Lofrans Touch Panel Controller - LWP74317

$495.49 -

Lofrans #477 Dog Clutch - LWPGP005

$88.00 -

Lofrans #341 Dog Clutch - LWPGP027

$133.12 -

Lofrans #458 Dog Clutch - LWPGP044

$175.42 -

Lofrans #343 Tigres Rope Drum - LWP817

$289.65 -

Lofrans Thetis 1002 Hand Held Remote Control - LWP73631

$220.56 -

Lofrans Thetis 5003 Hand Held Remote Control Chain Counter - LWP73632

$729.57 -

Lofrans #478 Tigres Main Shaft - LWPMS012

$319.26 -

Lofrans #919 Low Profile X2/Project 1000 Mainshaft - LWPMS040

$288.24 -

Lofrans X2/Project 1000 Topworks - LW7921LT-5/16

$1,388.09 -

Lofrans X1/Project 500 Low Profile Vertical Windlass - LW7911L-1/4

$2,139.67 -

Lofrans #467 Falkon Chain Stripper - LWPCP030

$188.11 -

Lofrans #447 Falkon Ratchet Wheel - LWPGP038

$391.17 -

Lofrans #327 Dog Clutch - LWPGP005C

$95.05 -

Lofrans #356a Anodized Cayman Motor Cover - LWPHP061

$268.51 -

Lofrans #465 Anodized Falkon Motor Cover - LWPHP011

$447.59 -

Lofrans X4/Project 2000 Seal Kit - LWPKA26101

$189.52 -

Lofrans Type C Control Switch - LWP610000C

$78.13 -

Lofrans Mini Remote Control - LWPMINI4

$410.89

About Windlasses

Featured Brands

Defender offers a complete range of anchor windlasses from industry leaders such as Lewmar, Maxwell and Lofrans. Whether you're looking for a vertical or horizontal windlass, with or without capstan, stainless steel, aluminum, or chrome-plated brass, you'll find it here at a great price.

Windlass Definition

A mechanical device called a boat windlass is used to control an anchor chain.It normally comprises of a vertical spindle or "wildcat" attached to the drum, a horizontal drum or "gypsy" mounted on the boat's deck, and a motor that propels the spindle.

The anchor and its chain are stowed on the drum when not in use and are raised and lowered by the windlass. One key component of a windlass is the gypsy, which is a grooved drum that is designed to grip the anchor chain. The chain is fed through the gypsy as the windlass is operated. The size and type of gypsy will depend on the size of the vessel and the size of the anchor chain used.

Another essential part of a windlass is the solenoid, an electromechanical device used to control the motor that drives the windlass.

A switch or other control activates the solenoid, converting electrical energy into mechanical energy, which is used to rotate the spindle and turn the drum.

The solenoid is a critical safety feature, as it allows the operator to stop the windlass in case of a problem or malfunction.

In summary, a boat windlass is a vital piece of equipment used to handle a vessel's anchor chain. It consists of a gypsy, a spindle, and a solenoid, and a motor controlled by the solenoid operates it. A windlass is an essential tool for any boat owner, and it is crucial to understand how it works and how to maintain it to ensure safe and reliable operation.

Several well-known brands of boat windlasses are widely used in the marine industry. Some of the most popular brands include Lewmar, Lofrans, and Muir.

Lewmar is a UK-based company manufacturing marine equipment for over 50 years. They offer a wide range of windlasses for use on boats of all sizes, from small pleasure craft to large commercial vessels. Their windlasses are known for their durability, reliability, and ease of use, and they come in various styles and configurations to suit different needs and preferences.

Lofrans is another well-respected brand known for its high-quality windlasses and other marine equipment. Based in Italy, Lofrans has been in business for over 40 years, and they have a reputation for innovation and attention to detail. They offer a range of windlasses suitable for use on boats of all types and sizes, and their products are known for their performance and reliability.

Muir is an Australian company producing windlasses and other marine equipment for over 80 years. They offer a wide range of windlasses that are suitable for use on boats of all sizes, and their products are known for their durability, reliability, and ease of use. Muir windlasses are widely used in the marine industry and have a reputation for quality and performance.

Finally, there are a number of well-known manufacturers of boat windlasses on the market, including Lewmar, Lofrans, and Muir.

These manufacturers provide a selection of windlasses ideal for use on boats of all shapes and sizes and are renowned for their high-quality goods and dependable performance.

Windlass Selection Guide

There are a number of important criteria to be considered in selecting the correct windlass for your boat and anchor.These include the vessel length and beam, displacement, windage (the vessel’s topside surface exposed to the wind), anchor size, and rode selection.

Practicalities such as locker space and depth of fall for the rode are also important in deciding which windlass is ideal for you.

Vertical or Horizontal Orientation:

The two basic configurations of windlasses are differentiated by the drive shaft orientation.Deck thickness and underdeck space are the two primary considerations when deciding which orientation will work best for your application.

Vertical windlasses are characterized by situating the capstan and/or gypsy above the deck and the motor and gearbox below.

Vertical windlasses provide a 180° wrap of the anchor rode around the gypsy giving optimal chain control, minimizing slippage and jumping.

Horizontal windlasses are mounted completely above deck with the gypsy and capstan located on either side of the motor.

They provide a 90° wrap of the anchor rode around the gypsy.

Space Required In My Chain Locker:

Locker space plays an important role in deciding whether to install a vertical or horizontal windlass.Estimating or measuring the depth of fall of the rode into the anchor locker may dictate which type of windlass is most suitable for your vessel.

Fall is the distance between the bottom of your windlass (horizontal) or windlass motor (vertical) and the top of the rode when the anchor is stowed.

The length of chain and/or rope, along with the type of rope (8-plait or 3-strand), must also be taken into account.

8-plait line is better suited for small lockers and the design of the line helps prevent hockling.

The depth of fall is the same for chain only rodes and rope/chain rodes.

The minimum recommended fall for anchor rodes is 12 inches.

The windlass does not stow the rode in the locker, gravity does.

Rode Selection:

Rope and, particularly chain, selection is extremely important.Windlasses are designed to take chain only, rope only, or both.

Rope/chain windlasses are now commonly used on boats up to 65 feet.

Chain only rode remain popular on heavier displacement sail and motor yachts.

The gypsy of the particular windlass will determine both size and type of chain which can be utilized, most new windlasses now specify HT chain, but this is not universal.

Long or regular link chain should not be used with anchor windlasses.

If the chain is not matched to the gypsy problems may occur, such as the chain jumping off the gypsy or the chain jamming.

If you are using a rope to chain rode you must make sure the size of the chain and the size of the rope match the specifications for the windlass gypsy.

Also, the rope must be spliced to the chain.

It cannot be joined to the chain with a shackle or any other mechanical coupling device.

Pull Capability:

The most useful way to rate windlass performance is by looking at what it will lift and at what speed.The two things to consider are the working load and the maximum pull capabilities of windlass.

Working load is the load that the windlass is pulling once the anchor and rode are off the bottom.

Maximum pull (sometimes referred to as stall load) is the maximum short term or instantaneous pull of the windlass.

Maximum pull capacity of your windlass should be 3 to 4 times the working load.

Safety Tips:

Accessories such as chain stoppers or chain snubbers must be used for safe anchoring, the avoidance of unintentional self-launching of the anchor, and for the prevention of damage to your windlass.When the windlass is not in use and the boat is at anchor, the chain should be secured using a chain stopper or snubber, or the rope rode should be attached to a load-bearing point such as a cleat.

You should never use your windlass to pull your boat to the anchor spot.

The windlass is designed to lift a dead weight and should not be subjected to the strain of your boat riding at anchor.

When your anchor is stowed and/or you are under way, an anchor snubber should be used to take the load off of the windlass and to assure the anchor does not accidentally deploy